Performance Upgrades for EEC-IV

Do you feel the need to

do the quarter mile in 12 seconds? Oh I

know, how about a 600-horsepower small block tow rig. Or maybe you want to smoke half your tread life away in seconds

next to that unsuspecting Chevy just to prove you can! We could just squeeze another 40-horsepower

out of that stock engine you already have, but that’s not as much fun. Well EEC-IV is currently our best “factory”

engine computer choice. I’m going to

talk a lot here and explain some fundamentals; we’re going to cover what to do,

and what not to and hopefully in the end you’ll have an idea of where to go

from here. Most of you however, will read

this, get lost, scratch your heads, question my sanity, and make your own

plans. What ever you do take this one

line to heart. There is no master book

on performance mods, all vehicles respond differently to upgrades, the most

successful people experiment and learn the fundementals. Performance

upgrades can make big gains, but I will start with a short list of stuff not to

do, just to keep you from thinking about hurting your Ford. All these are not good ideas, unless you

have a large game plan and know what your doing.

·

Thermostat

changes under 180°

o This only tricks your EEC and hurts your

engine; leave this trick for the drag strip.

·

Altering ECT

or ACT

o This only tricks your EEC and hurts your

engine.

·

Unhooking EGR

o If you are going to do this; unhook all the

related sensors telling the EEC to skip the EGR in the Flow-Chart. If parts are left, you run the risk of A/F

ratios being incorrect and dangerous.

o EEC turns off EGR at WOT

·

Changing fuel

pressure

o This is something only needed for real big plans,

I’ve seen engines make well over 500RWHP with only 40PSI

·

Changing MAF

o Not meant for stock engines, this is only to

be included in big plans, not a performance mod in its self. Read about MAF under sensors.

· Adding or changing Injectors

o For details on this read about injector under actuators

Sorry for ruining some of your plans but if you keep reading we are now starting to make plans for the big power gains. Lets cover the basics quickly, engines are just big pumps, and the more air and fuel they can pump the more power they make. Air + Fuel + Spark = Power, more of each at the right times makes more power. You will have to start with some basic engine work to make you engine require more air and fuel. You can’t just slap on a high tech EEC system and expect any gains in power. Most vehicles however are born in the factory with some horsepower hidden inside. I won’t go into which intake is better than the other brand, or cylinder heads that are king. This is just like drivetrain upgrades; we have start with the weakest or most restrictive part. I will try to explain where to go for certain results. I am no engine builder nor can I guaranty power gains for certain combinations; I am just reciting common knowledge. You can even call up a major aftermarket dealer tell them what you have and where you want to go. Summit, Edelbrock, Ford Performance Parts, and Trick Flow all have matched parts, kits, and toll free hot lines waiting to help you spend money.

Camshafts

Contrary to popular belief, a bigger cam will not necessarily make more power; in fact it can sometimes cost you performance. Stock cams actually have a very efficient profile and can propel a naturally aspirated Mustang into the 11's with the right pieces. Larger cams might make a little more power but will generally shift the power band of an engine upwards. Even if your engine’s internals are up to the task of making runs 6000+RPM the heads and intake reach peak power right around 5000 rpm, so it doesn't do any good installing a cam that makes peak power at 4700. If your car has stock heads, intake, or both, installing a larger cam is a waste of time and money because your car will most likely go slower. Large cams that change engine vacuum will confuse a Speed Density EEC that will improperly sense load. Large cams that cause a surging or pulsing of air at idle will confuse Mass Air Flow, making EEC idle quality suffer. On the other hand, if you've got a good matched set of high flow cylinder heads and intake, a cam change can be worth the effort. If you still feel the need to change the bump stick try to keep the lobe separation of the cam above 113 degrees. Lift should stay under 0.5” when using 1.6:1 rocker arms, any more might create an interference engine if the chain goes. When the time comes that you want to make cam changes you run the risk of needing the EEC programming changed.

Intake

Manifolds

Intake manifold changes are pretty straightforward. This new EFI gives tuners more flexibility; we can now tune the intake without worrying about fuel atomization. Longer intake runners create torque in lower RPM range, while shorter intake runners create torque in the upper RPM range. There is a third consideration, larger / shorter intakes create upper RPM horsepower. The intake for your Ford is something you need to consider very carefully, the more your car weighs the more low end you need to get it to start moving. Don’t put your power band from 2500-6000RPM if you only commute to work. For F-150 and Bronco’s I recommend staying with the stock intake, going with a GT-40 set-up like the Lightning’s, or Edelbrock makes a truck intake for 302/351 that uses stock TB and improves flow without ruining your low-end power.

Larger stroked 351’s can use other intakes and still have enough low-end grunt to move that land yacht of yours. If you do use a Mustang specific intake manifold I suggest adding a heat spacer, not for better air temps, but to lengthen your intake runners. Longer runners are better for low-end torque.

Don’t forget to include

larger throttle bodies, MAF sensors, and a low-restriction air filter in your

plans to improve breathing. Keep the

MAF calibrated to your stock injectors unless you want to recalibrate your

EEC. As with all power adders, the more you add the more your chance of

needing your EEC programming altered.

Cylinder

Heads

"More air and fuel in, more power out." That’s what good cylinder heads can do. They allow the engine to breath more

efficiently, which in turn makes more power.

The potential of any engine is limited by its cylinder heads. You can try to push more air and fuel into

an engine with a blower or nitrous, but the amount you force in is still

limited by the efficiency of the cylinder heads. Bigger is not always better when cylinder heads are involved. Port shape and configuration are much more

important than size, first match them to your intake. A port that is too big on a relatively mild engine can actually

make the car run slower than stock. You

have to think about more than just size, a larger port does not always flow

more air, shape is everything. Check

airflow numbers and calculate what your engine needs. As with everything else, the right combination of pieces will

make the most power, not just buying the best numbers out of a catalog.

Supercharging

/ Turbocharging

This one needs little explanation, pump in air, and you have more power. This won’t work on Speed Density EEC’s, you’ll need to reprogram it or upgrade to MAF. Things to look out for are heat, if pressure melts ice during a hockey game; pressure also increases intake air temp and engine temp. Rising air temperature will decrease its density. Remember speed density, the cooler the air the denser air, engines burn pounds of air not cubic feet. Big pressure will need spark retarding, and a larger fuel pump. Don’t increase injectors or fuel pressure, we need more flow not more pressure. MONDO pressure will need more pressure and spark retarding than the EEC can handle, I recommend tuning the EEC when fuel pressure changes are made. Timing tables need to be retuned as well for the big pusher. Kenne Bell sells a good supercharger that adds boost to the entire RPM range, which is important for big trucks and low RPM power.

Nitrous

Nitrous Oxide is by far the biggest bang for the buck. Fact, you can make no performance

modification for the same amount of money that will yield the performance gains

of nitrous. Since Nitrous is only used

at Wide Open Throttle it does not affect streetability or gas mileage when it's

not being used. Unless you open the bottle

you have no effects of nitrous. Nitrous

systems for EFI systems are a simple plate that mounts between the intake. Expanding nitrous cools the intake air

charge by 60° - 75° F, which is alone worth horsepower. When a system is installed properly and

jetted / tuned to a level the engine is comfortable with, there are no adverse

effects to Nitrous Oxide use. Nitrous

systems have their own fuel supply; this means most EFI systems need no

additional tuning to operate with nitrous.

For sprays greater than 100HP you will need a strong engine and retard the ignition

timing by 4-8 degrees (1 to 1-1/2 degrees timing retard per 50 HP gain.)

There are some new nitrous systems that add nitrous as load increases,

this may need EEC tuning at the very least and possibly a new engine management

control system other than EEC. If you

need a power builder on a small budget, spray it.

Increased

Displacement

Do I really need to say

any more? “There’s no replacement for

displacement.” Swap from a 302 to a

351, or a 351 to a 460, just follow the factory-mounting plan or get

aftermarket engine mounts. Stroke you

engine; 302’s up to 360, 351’s up to 454, and 460’s up to 815. If

you can build the engine and have the EEC tuned to match the displacement of

the engine you’re building, I can guide you to wiring the injectors to match

the firing order. Just go read about

that on the Harness Page.

Ignition /

Spark Controllers

This is a touchy subject; everyone thinks they need one and that they will get big gains from it. NOT true, why do you need one? A well-tuned, normal compression street engine has no need for greater spark. A poorly tuned engine will burn cleaner and get a little help, but if you tuned it first you would get better response. If you’re running higher compression, adding boost or nitrous then it could be needed. Higher pressures and violent conditions inside the combustion chamber are very hard for a spark plug to ignite. It’s like lighting a match in a windstorm. Multiple, longer, and stronger sparks are now needed. If you’re interested, my opinion is that MSD has more options than anyone else and Crane Cams base model has most of the water proof / vibration proof features that cost extra in other brands.

One thing you can do for

added performance is easy and free. You

can adjust the base timing a little greater than 10°BTDC. Try 12, if that works

without detonation, try a little more.

I sugest staying at 14° or under, any more and you’re really asking for

93 octane fuel or better. Just keep

your ear open for detonation, or else you’ll be buying new pistons.

Exhaust

This is also a simple one, bigger flows more. Mandrel bends and free flow mufflers have fewer

restrictions. Summit, MAC, Ford Racing

Performance, Bassani, Borla, Flowmaster, and Dynomax are all companies that

sell quality exhaust parts. Look at you

frame rails, firewall, front drive shaft, and where you want the exhaust to go. You can buy exhaust with provisions for O2

sensors or weld in O2 sensor "bungs" into the exhaust. But be careful that they don’t hit the

firewall or make it too hard to replace them.

Don’t underestimate your local exhaust shop, but make sure they’re clear

on what you want. MAC sells a good set

of equal length headers for 302, 351, and 460’s all EFI compatible. The 302 headers work with 4WD and all spark

plug angles.

Gears and Tires

This has all been covered before. Just make sure you match you power band range. If you range is idle-4000, try to make your final drive run on the highway at 1800RPM with overdrive. Like wise if your range is 2000-7000 with a well-built engine, final drive on the highway should be about 2800 with overdrive. But the higher your power range and drive ratio you’ll be shifting more and losing streetablilty. Higher gears always give you that funny back of the seat acceleration feeling, and open differentials just spin one tire.

Fuel System

The fuel system should only be upgraded when your engine is being starved for fuel. The stock fuel delivery system can provide enough fuel for 350horse engines. You can get a better fuel pump, add a fuel pump, or increase the voltage to the stock fuel pump. Sometimes all you need is larger fuel lines to feed the engine. All are very acceptable and have proven results. Make sure you’re providing more fuel than your engine burns, set up a gauge off the test port and run it full throttle a few times, make sure the pressure stays constant. More power means more flow. I’ve seen engines make well over 500RWHP with only 40PSI, so you typically need more volume not pressure. The injectors can always be upgraded to provide more fuel, the higher the injector rating the more amps it requires to operate it. A stock EEC can’t more than 2 amps per injector, and stock 19lb injectors draw 0.75 amps. I think 50 lb injectors are the limit; keep this in mind when buying larger injectors. Fuel pressure and injector upgrades always require the EEC to be reprogrammed to go along.

Upgrading

the EEC

Now we get to the meat and potatoes, the reason you’re reading

this. The EEC-IV is one of the most

efficient engine management computers in the industry and does an extremely good

job of producing power even with the factory Ford programming. But if your building an engine that has

needs outside the programs Look-Up-Tables then you will need to adjust the

program. EEC can handle almost any

engine you can build with the right computer program. Never lie to an EEC, use the correct injectors, sensors,

displacement, and fuel pressure that the program is expecting. If you have reached a point that you want

more power, and injectors, fuel pressure, or displacement changes are made, the

EEC will need to be changed. One thing

that a lot of people run into with power upgrades is drivability problems. These are caused by the engines requirements

not matching the EEC’s programmed values.

The EEC has Look-Up-Tables that indicate where the engine is in the

program, an idling 460, will crave the same amount of air as, say a 302 at

2500RPM. If you go read about sensors and strategies you will see that you can

build an engine that moves up the scale a bit but your engine can’t max out

those look-up-tables with out getting major drivability and performance

losses. Another problem is superchargers

and turbochargers, these will make a stock Speed-Density EEC go completely

crazy. Once tuned properly speed

density can handle big power engines better than MAF, while MAF can give the

moderate engines more street manners.

At this point you’re all pondering putting the 4-barrel back on the

engine, keep reading it will all be okay.

EEC can make a performance engine produce reliable power repetitively

and give you an ease of mind.

So you have beefed up your engine and made the decision to change the

EEC operating system, now you have a few options. There is no one book that has a detailed explanation of

everything in the Ford EEC and exactly how to tune your car. Ford try’s to keep this stuff from getting

out; if anyone could do it then Ford wouldn’t have a market. This art needs a lot of planning and ablity

to learn basic facts and therories without classes. Make a list of your engines requirements and the current amount

in your bank account and keep on reading.

·

Speed Density

to MAF conversion

o Works great for moderate engine builds

o Can be done with junk yard parts if you’re

good

o You only need one more sensor

o You better read the Harness Page a lot

·

EEC with

Performance Chip

o You can cure 99% of engine dynamics

·

Separate

Transmission Controller

o

It’s easier to

program one computer for one function

o

Take control

of all transmission functions for another $500 - $600

·

Aftermarket

Computer

o With the proper training, skill, & money

you could cure the cold.

o The sky’s the limit, horsepower and cash are

relative

·

EEC-V

o

Put a 21st

century features into your car

o

Expect to

spend years of planning

o

Wiring

nightmare

Most people debate Alpha-N vs. Mass Air vs. Speed Density, and Open Loop vs. Closed Loop. Lets talk about doing a “Mass Air Conversion;” a stock mass air system can tolerate moderate engine changes and still work great. Some will talk about sequential firing injectors as a performance upgrade, not directly true. The truth is that you will gain a small percentage of fuel economy, but the performance gains are usually tied to the MAF sensor getting air to fuel ratios correct. Bank injector firing Mass Air systems can dyno just as much power as a sequential injector firing system. Improving flow into a speed density system will not always get big gains, you will probably need to upgrade to MAF. A MAF can cost you up to $2000 if you like to keep your hands clean, or you can use some skill and junkyarding and do it for under $200. This job is more about wiring than anything else, you will have to mount a MAF sensor between the air filter and throttle body. Many times you can run two computers, one for the engine and a separate for the trans, an EEC or TCS can be used. Again this is mostly wiring issues, read the harness page, and then ask some questions.

Open-Loop condition is when the

computer takes only the settings in the computers tuning program to adjust a

vehicles air to fuel ratio. Closed-Loop

is when the computer takes feedback from an 02 sensor to correct or change the

air to fuel ratio to a desired point.

Stock EEC’s only use closed loop during warm cruising situations for

perfect fuel economy and emissions, this is A/F of 14.7:1. Aftermarket engine control computers can go

closed loop over all operating conditions. Many racers use the 02 sensor feedback to

adjust air to fuel ratio’s to the desired level, like 10:1, this needs a

special HEGO. Some leave it open loop

as a false rich condition can cause the computer to incorrectly remove fuel

from the calibration, thus harming the engine from detonation. Open-Loop vs. Closed-Loop is a big debate

and not a huge deal to EEC owners. More

on this in the sensors page.

After making the jump to Mass Air (or you’ve had it while) and you’ve

made one too many upgrades. Idle

quality is starting to suffer, or Wide-Open-Throttle isn’t what it should be,

or maybe both aren’t right. A custom

chip should be a consideration once you have all the performance parts

together, not when the engine is mostly stock.

I recommend reading about EEC strategies a little before reading

on. Chips can’t put performance into a

stock engines, what a chip can do incredibly well is fix drivability problems,

and give back that kick at full throttle.

After reading strategies you’lll wonder what “good” a chip can do; here

is the Chip Menu.

·

Reset Idle RPM

(fix a surging idle the right way)

·

Change RPM

Limiter (6200RPM factory limit)

·

Fix Cold

Startup Problems

·

Setup an

optimized timing curve (a boost/nos timing custom curve)

·

Change MAF

meter calibration

·

Change

Injector Size (while keeping the old MAF curve)

·

Change Cubic

Inches (fix idle/part throttle issues)

·

Change WOT

fuel curve (for increased performance)

·

Change Part Throttle

fuel tables (to fix bucking)

·

Correct the

A/F ratio when long tube headers are added.

·

Remove Speed

Limiters/Torque controls

·

Change the

temp that the electric fans are turned on/off

·

Change O2

readings for location/heat change

·

Turn off O2 readings

for 100% open loop operation

·

Turn off EGR

operation

·

Turn off

emissions Air Pump controls

·

Anti-theft

program

·

Valet Program

·

Have a total

of 4 different programs for different driving conditions

·

Fix the

speedometer on 99-up vehicles

·

Change torque

converter lock-up

·

Change the

shift firmness on AOD-E's (no need for a shift kit)

·

Change the

shift rpm's on AOD-E's

What is a good chip? If you just

need a better timing curve try twisting the distributor, its cheeper and just

as effective. Ford base setting is

10°BTDC, you could add a little to suit your needs. If you need bells and cool blinky lights you could just get a new

aftermarket engine computer. Aftermarket computers are only recommended for people that

are upgrading regularly, and for those that have more knowledge on this than

me. These plug-in chips can be

“re-tuned,” so if you do yearly upgrades a performance chip is still your best

option. Once you start changing blower

pulleys, swapping intakes, cams, and reporting your heads every month you’ll

want to step out of tuning EEC with a chip and go for an aftermarket engine

controller. But if you are

reading this for advice, don’t even think of tuning your own EEC at this

time. With a novice using their own

tuning software, engine failure is now only a few keystrokes away. There are many professionals out there that

have tuned over 10,000 vehicles each without hurting the customer’s

engine. Mike

Wesley is probably the best tuner / chip burner in the country. Good luck finding him, he has gotten into a

few lawsuits with Ford Motor Company claiming “he must have used spies.” He is the one that hacked into the EEC and

invented the Autologic Software that is the basis all other chip companies use. Other reputable tuners for Ford’s EEC are Lidio

Iacobelli @ Alternative Auto, Chris Johnson @ JMS

Motorsports, Jim LaRocca, Joe Mainero @ UPR, Byron @ R.A.C.E. Systems, Sean

Hyland, and Powertrain technologies.

These guys can also make EEC-V putty in there hands. They are so good that some of them can take

your order over the phone and mail you a chip to install your-self. It won’t be as perfect as in-house and dyno

tuning, but this is very acceptable for moderate upgrades. I do not recommend ordering a chip from a

catalog or over the Internet; you at least need to talk to a person on a phone.

There are a lot of people that have the misconception that

chips must be made using a dyno, very not true. Mild chips can be made with a phone interview and moderate

performance engines can be in-house tuned with real world situations. This is where you leave the vehicle with

them and they drive it under many different situations while recording all

engine parameters, and then adjust the chip until its perfect. You get better streetability and fuel ratios

this way. Scheduling dyno-tuning is

only needed if you are trying to squeeze another 2/10th out of your

quarter mile, and costs more. Dyno

tuning still starts with taking real world driving data as before, just adds

finishing touches by comparing dyno numbers.

Most people get suckered into dyno-tuning because the idea of having a

“Dyno” run print out afterwards sounds cool.

For mild engine build mail order chips are okay.

Lets go over how to install a chip or other electronics into

EEC. You need to remove the EEC from

the vehicle, and every one is different.

I have a page made up to help you locate the EEC in your vehicle. Remove it from the vehicle and then the

60pin connector. Loosen the bolt head

on the top of the EEC where the 60pin connector meets the EEC, a 10mm socket

will work. Keep in mind the bolt will

not come out of the harness, rather when it has disengaged itself from the EEC

module it will freewheel. Then pull the

60pin connector out of the EEC. Now

take the EEC somewhere safe to work on it, I say the kitchen table, why? This has to be careful clean work, if your

getting too messy for the kitchen table you need to slow down and be more

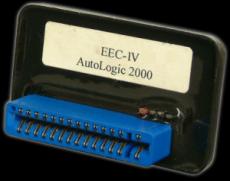

careful. These are some examples of EEC

computer module’s (better known as chips)

The tuner chip itself

plugs into the J3 test port of the EEC.

This is a close up of the J3 test port. The J3 test port was intended for last minute testing in the factory, and then is was sealed never to be used again. But this is the best way to add to the programming, NEVER solider a component on of off the board. This in mind we have to clean the J3 to use it again. It is imperative that you clean these contacts, if there isn't good contact in this area, you will have problems. Use a swab to wipe off the protective grease, and then scrape off the solder mask (usually green in color.) Super fine sandpaper, steal wool, and even small screwdrivers will work; make sure you do it to both sides. There should be 15 contacts on each side. After all your hard work spray a little electronics cleaner to finish up the work.

Some times you can clean and install the chip with out removing the cover. But to clean your best you should remove the cover. There are four Torx retaining screws on the top center and two more at the rear corners. Once these are out, you can remove the cover, just as below. But not on the floor of your car, this isn’t the cleanest, safest, or static free environment you need. Don’t be scared to open it or work on it, just don’t get sloppy.

If your chip required you to open the EEC, and mount it inside, do that now; make sure to use the supplied foam insulating blocks. Follow all manufactures directions, any installation differences’ should be done as they ment. Any questions should be directed to the chip manufacturer. Make sure you connect the chip with the correct orientation to the board and make full contact with the J3 port.

Now you can close up the

EEC, some higher end models with more than one program will have a leading wire

harness. Route this harness safely to

the switch. Place on any suplyed

grouments and seals. Then re-instal

your EEC to the vehicle.

ã

Copyright 2003 Fordfuelinjection.com, a division of RJM

Injection.

Fordfuelinjection.com is not affiliated with Ford Motor Company.