Engine Smoothness

V8 engines

May I say all V8s are 90°

? really, I haven’t heard any non-90° V8. 90° is the only configuration

achieving good balance for V8. However, there are two types of crankshaft

arrangements, which delivers very different characters. They are cross-plane

crankshaft and flat-plane crankshaft. Most of the world’s V8s are cross-plane

V8, including all American V8s and all sedans’ V8s. However, the most exotic

European sports cars, including Ferrari, Lotus and TVRs, employ flat-plane

V8s.

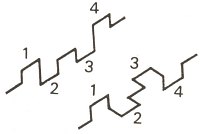

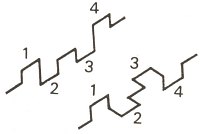

Flat-plane V8 (left)

and Cross-plane V8 (right)

Flat-plane V8 (left)

and Cross-plane V8 (right)

|

Share the same crank

pin

Share the same crank

pin

|

No matter which kind of

V8s, they have 5 main bearings. A cylinder in bank A shares the same crank

pin with the corresponding cylinder in bank B, therefore the crankshaft

of V8 is actually simpler than V6. Both V8s generate no vibration in vertical,

transverse directions or between bank and bank.

Cross-plane V8

However,

for cross-plane V8s, there is vibration from end to end of the engine,

this is because the first piston of bank A is not in the same position

as the last piston of bank A (the same goes for bank B), unlike an inline-4

engine. No problem, the 90° V8 solves this problem by introducing an

extra-heavy counter weight to every cylinder. The counter weight is heavy

enough to balance the weight of crank throw, con-rod and piston of that

cylinder, thus resulting in lack of vibration.

However,

for cross-plane V8s, there is vibration from end to end of the engine,

this is because the first piston of bank A is not in the same position

as the last piston of bank A (the same goes for bank B), unlike an inline-4

engine. No problem, the 90° V8 solves this problem by introducing an

extra-heavy counter weight to every cylinder. The counter weight is heavy

enough to balance the weight of crank throw, con-rod and piston of that

cylinder, thus resulting in lack of vibration.

Now you must be wondering

why such counter weight is not used in other kinds of engines. It is because

this counter weight must be used in 90° V-type engines which have shared

crank pins. It our previous study, you’ll find only V8 fulfills all these

requirements. Why are there such requirements? good question. As you know,

all engines have counter weights just enough to balance the weight of crank

throws and part of the connecting rods, leaving the remaining weight of

connecting rods and the whole, all-important pistons unbalanced. This is

because the rotating counter weight can only balance rotating mass. Unluckily,

the whole piston moves vertically rather than rotates about the crankshaft,

while the CG of con-rod is somewhat rotating but also somewhat going up

and down. If we insist to use heavy counter weight, it will cause side

shake.

|

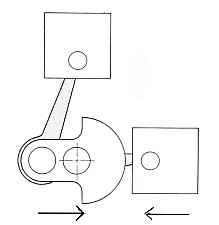

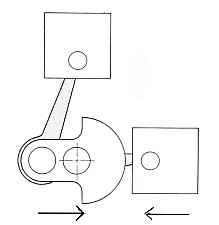

Considering the illustration.

Assume the counter weight in vertical position is heavy enough to balance

the crank throw, con-rod and pistons. When the crankshaft rotate 90°,

the counter weight is repositioned to the right, but the piston doesn’t

go to the left, and the con-rod just partially moves to the left. Only

the crank pin moves completely to the left. Now you can see the system

is not balanced. The counter weight will generate a net force towards the

right.

However, for 90° V8,

when such a heavy counter weight moves to the right, the piston from another

bank will cancel it completely, because their movement are exactly opposed

at this moment. (see illustrations below) The same result can be found

for the counter weight moving to the left. Therefore 90° cross-plane

V8 employs full-weight counter weights can achieve near perfect smoothness. |

Flat-plane V8 for high performance cars

However, the disadvantage

of cross-plane V8s is also about the counter weights - not only increase

the weight of engine, they also contribute to rotational inertia, thus

making the engine less responsive and less revvy, dropping upper rev limit

and top-end power. Moreover, the larger counter weights usually requires

a larger crankcase to house them, thus raising the height (and more important,

center of gravity) of the enigne. Therefore Ferrari all V8 models, TVR

Cerbera AJP V8 and Lotus Esprit V8 employ flat-plane V8s instead.

Flat-plane

V8 is named according to the shape of the crankshaft, which is in a flat

plane. It is very much like two inline-4 engines mated together. In particular,

it achieves end-to-end balance because the first piston and last piston

of a bank is exactly in the same position, so are the center two pistons.

This is just the same as straight-four engines, therefore the sound of

flat-plane V8 is usually somewhat like a pair of four-pot engines screaming

simultaneously, unlike the rumble-bumble of cross-plane V8s.

Flat-plane

V8 is named according to the shape of the crankshaft, which is in a flat

plane. It is very much like two inline-4 engines mated together. In particular,

it achieves end-to-end balance because the first piston and last piston

of a bank is exactly in the same position, so are the center two pistons.

This is just the same as straight-four engines, therefore the sound of

flat-plane V8 is usually somewhat like a pair of four-pot engines screaming

simultaneously, unlike the rumble-bumble of cross-plane V8s.

As both banks run like an

inline-4 engine, there is second-order vibration. For a 90° flat-plane

V8, the sum of second-order force generated in the 2 banks is - by simple

vector analysis - 1.41 times (root-2) of the force generated by each of

the inline-4 it consists of. And the direction of vibration is left-right

instead of top-down. In other words, while displacement increases 100%

compare with the inline-4, the second-order vibration increases just 41%.

That makes the flat-plane V8 more refined than an inline-4 although it

is not as smooth and quiet as cross-plane V8.

To exotic sports cars, less

refinement is not a big problem. Especially they usually employ short stroke

and light weight pistons / con-rods, the second-order vibration is greatly

reduced.

V10 engines

Theoretically, the best V-angle

is 72°. Like two inline-5 mated together, there is no vibration in

vertical and transverse directions, but there is vibration from end to

end of the engine, thus require a balancer shaft install in the V-valley

for best balance. However, there is no vibration between bank and bank

because pistons in both banks are in the same positions.

V12 engines

Theoretically the best balanced

configuration for practical use. It is simply a duplication of inline-6

(therefore achieve the same perfect balance), with corresponding cylinders

in both banks joined at the same crank pins. V12 is better than inline-6

just because it has more cylinders, thus doubling the firing frequency

and smoothen power delivery.

Of course, the disadvantages

are cost, size and weight.

There’s no structural differences

in crankshaft for all V12s, no matter for luxurious cars or supercars.

Most employ 60°, although Ferrari prefers 65°.

Lamborghini's 60°

V12 for Diablo GT

Lamborghini's 60°

V12 for Diablo GT

|

McLaren F1's BMW 60°

V12

McLaren F1's BMW 60°

V12

|

Copyright©

1998-2000 by Mark Wan

AutoZine

Technical School

Return

to AutoZine home page

However,

for cross-plane V8s, there is vibration from end to end of the engine,

this is because the first piston of bank A is not in the same position

as the last piston of bank A (the same goes for bank B), unlike an inline-4

engine. No problem, the 90° V8 solves this problem by introducing an

extra-heavy counter weight to every cylinder. The counter weight is heavy

enough to balance the weight of crank throw, con-rod and piston of that

cylinder, thus resulting in lack of vibration.

However,

for cross-plane V8s, there is vibration from end to end of the engine,

this is because the first piston of bank A is not in the same position

as the last piston of bank A (the same goes for bank B), unlike an inline-4

engine. No problem, the 90° V8 solves this problem by introducing an

extra-heavy counter weight to every cylinder. The counter weight is heavy

enough to balance the weight of crank throw, con-rod and piston of that

cylinder, thus resulting in lack of vibration.

Flat-plane

V8 is named according to the shape of the crankshaft, which is in a flat

plane. It is very much like two inline-4 engines mated together. In particular,

it achieves end-to-end balance because the first piston and last piston

of a bank is exactly in the same position, so are the center two pistons.

This is just the same as straight-four engines, therefore the sound of

flat-plane V8 is usually somewhat like a pair of four-pot engines screaming

simultaneously, unlike the rumble-bumble of cross-plane V8s.

Flat-plane

V8 is named according to the shape of the crankshaft, which is in a flat

plane. It is very much like two inline-4 engines mated together. In particular,

it achieves end-to-end balance because the first piston and last piston

of a bank is exactly in the same position, so are the center two pistons.

This is just the same as straight-four engines, therefore the sound of

flat-plane V8 is usually somewhat like a pair of four-pot engines screaming

simultaneously, unlike the rumble-bumble of cross-plane V8s.