Inline 6-cylinder

engines

As shown in the picture,

straight-6 engine is simply two 3-cylinder engines mated symmetrically

together, thus piston 1 is always in the same position as piston 6, piston

2 the same as piston 5 .... in other words, the engine is balanced end-to-end

and requires no balancer shaft, unlike 3-cylinder engines.

What about vertical / transverse

forces? like 3-cylinder engines, the vertical and transverse forces generated

by individual cylinders, no matter first order or second order, are completely

balanced by one another. The resultant vibration is nearly zero, thus inline-6

is virtually a perfect configuration.

Inline-6 is not the only

configuration can deliver near perfect refinement, but it is the most compact

one among them. All boxer engines are perfectly balanced, but they are

two wide and require duplicate of blocks, heads and valve gears. V12 engines

also achieve perfect balance, but obviously out of the reach of most mass

production cars. Automotive engineers knew that long ago, that’s why you

can see most of the best classic engines were inline-6, such as Rolls-Royce

Silver Ghost, Bentley Speed Six, Mercedes SSK, many Bugattis, Jaguar XK-series

and BMW’s various models.

V6 engines

V6 engines, excluding Volkswagen’s

15° VR6 (to be discussed later), are not just made from splitting inline-6

into two banks arranged in V-shape. A V6 has a very different crankshaft

- only 4 main bearings instead of 7. In other words, between two adjacent

bearings there are crank throws for 2 cylinders, one from bank A and another

from bank B. While V8 engines have those 2 cylinders shared the same crank

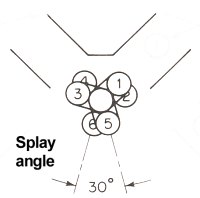

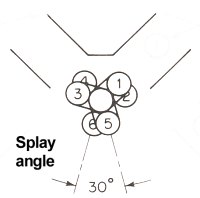

pin, V6 engine has to split the crank pin into two pieces, with a splay

angle between those pins (30° splay angle for 90° V6; 60° splay

angle for 60° V6). These are shown in below.

60° V6 with 60°

splay angle

60° V6 with 60°

splay angle

|

90° V6 with 30°

splay angle

90° V6 with 30°

splay angle

|

Split crank pins with

a 30° splay angle

Split crank pins with

a 30° splay angle

|

For better balance, most

V6s are arranged such that the banks are placed at either 60° or 90°

to each other. In this way, the movement of cylinders in bank A matches

those in bank B, thus there is no vibration generated between banks. Besides,

like 3-cylinder engines, there is no vertical and transverse vibration.

However, both 60° or

90° V6s have somewhat end-to-end vibration like 3-cylinder engines,

especially is for 90° V6. (sorry, I don’t have the theory) It needs

a counter-rotating single balancer shaft, at crank speed, to suppress the

vibration. The balancer shaft is located inside the V-valley, so it is

not space engaging. On the other hand, 90° V6 has a decisive advantage

in production point of view - it can be machined in V8’s production line

because both of them are 90°. (unlike V6, V8 can only be optimised

at 90°) This save a lot of production cost. An example is Mercedes’

supersmooth 2.4 to 3.2-litre V6s, which share the same architecture with

V8s but added with a balancer shaft.

End-to-end vibration

End-to-end vibration

|

Single balancer shaft

inside the V-valley

Single balancer shaft

inside the V-valley

|

60° V6 is smoother to

the extent that, with adequate design engine mount, most of them could

be made nearly as smooth as inline-6 engines without the need of balancer

shaft. It is also narrower, so easier to be packaged into a FWD cars, mounted

transversely.

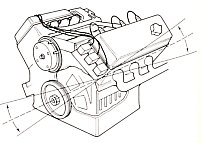

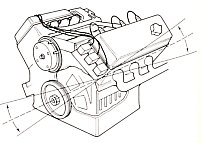

60° V6 versus Inline-6

As space efficiency becomes

more and more important, most car makers favour V6. The most influential

V6 was perhaps Alfa Romeo’s 2.5-litre 60° V6 used in the GTV6. It established

a reputation for V6 that it can be compact, powerful and smooth. An equivalent

inline-6 would have never fit the small and sloping engine compartment

of that car. Compare the shape of BMW with the Alfa and you’ll know the

packaging advantage of V6s.

Straight-six engines are

nearly impossible to be used in front-wheel drive cars as well. Even a

car as wide as Volvo S80 has to introduce the world’s shortest gearbox

in order to make space for the 2.9-litre straight-six mounted transversely

in the engine compartment.

Longitudinal mounted inline-6

doesn’t have such problems, but it engages too much space in north-south

direction, thus engage some space which would have contributed to cockpit

room.

However, BMW is still loyal

to inline-6 engines. Ultimately, inline-6 engine is more efficient yet

smoother. V6 has more energy loss because it duplicates valve gears and

camshafts (which increase frictional loss), while the use of 2 cylinder

banks leads to more heat loss. In terms of production cost, although V6

has 3 fewer main bearings, it has more valve gears - which is getting more

and more costly these days, with the introduction of twin-cam, hydraulic

tappets / finger follower and variable valve timing. Inline-6 is going

to be cheaper than equivalent V6.